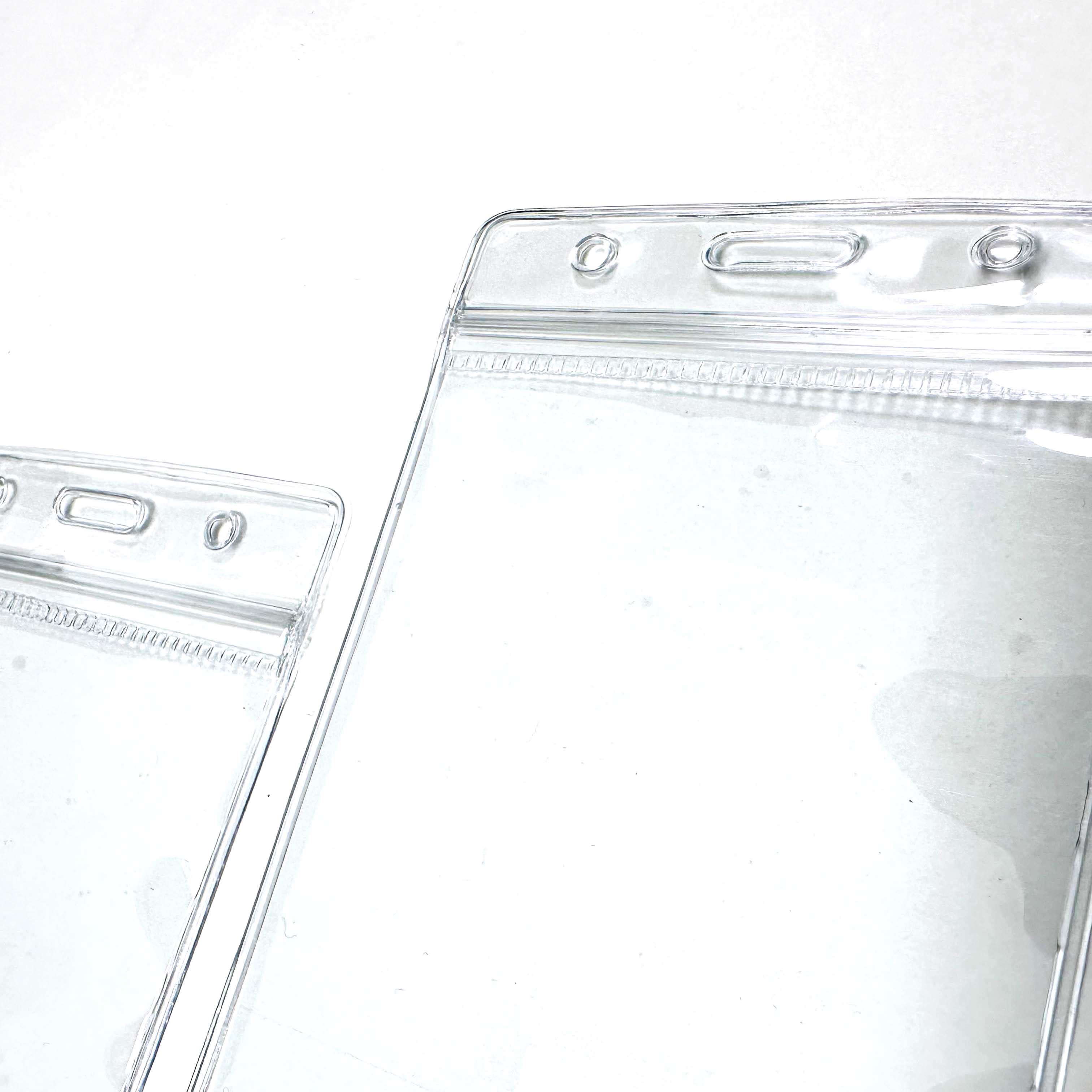

A Plastic Badge Holder with Zipper is a specialized accessory designed for the secure storage, display, and protection of identification cards, access passes, or credentials. Typically constructed from clear, flexible PVC or vinyl, the primary pouch allows for high visibility of the badge's content, while a zippered closure ensures the card remains encapsulated and protected from environmental damage. The holder often includes a breakaway Lanyard or a clip Attachment mechanism, facilitating easy carrying and quick release for safety. The dimensions are standardized to fit common card sizes, such as the CR-80 format (3.375 × 2.125 inches or 85.6 × 54 mm), with the plastic material thickness ranging from 0.1 to 0.3 mm to balance durability and flexibility. The zipper is usually made from durable nylon or plastic, tested for thousands of open-close cycles to prevent failure. Advanced versions may feature anti-static properties, UV coating to prevent fading, or RFID shielding materials (often a metallic mesh layer with attenuation up to 30 dB) to protect against unauthorized scanning of sensitive credentials.

Key Features with Professional Data

Material Clarity and Durability: The primary viewing window is manufactured from optically clear PVC or vinyl with a light transmittance of over 92%, ensuring minimal distortion and maximum readability of the badge's text, photo, and holograms. The material often has a hardness rating of 80-90 Shore A, providing sufficient rigidity to protect the card from bending or creasing while remaining pliable enough for easy insertion. The plastic is also resistant to common chemicals, such as mild alcohols and cleaning agents, which allows for surface disinfection without degradation.

Secure Zippered Closure: The defining feature is the full-perimeter zipper, which fully seals the badge within a protective environment. This zipper is typically a #3 or #5 gauge coil zipper made from molded nylon, which is corrosion-proof and has a minimum tensile strength of 50 kgf. This design offers a significant advantage over open-top or slotted holders, as it provides a 100% barrier against dust, moisture, and accidental loss. The zip puller is often designed for easy grip, even with gloves, and can be tested for over 10,000 cycles without a significant drop in performance.

Attachment and Safety Mechanisms: Most holders are equipped with a metal or plastic swivel clip that can be attached to a lanyard, belt loop, or Keychain. A critical safety component is the breakaway lanyard, which incorporates a magnetic or mechanical release mechanism that disengages under a specific force threshold (typically between 5-15 lbs or 2.2-6.8 kg). This is a crucial safety feature in industrial, healthcare, or laboratory settings where a lanyard could pose a snag hazard near machinery.

Environmental and Specialized Protection: For use in harsh environments, some holders are IP54 rated, offering protection against limited dust ingress and water splashes. RFID-blocking models integrate a thin layer of aluminum or nickel/copper alloy into the pouch walls, creating a Faraday cage that effectively blocks electromagnetic fields in the 13.56 MHz (HF) and 860-960 MHz (UHF) bands, preventing skimming of RFID or NFC chips embedded in modern access cards.

Application Scenarios

Corporate and Office Environments: In large offices and corporate campuses, employees use these holders to prominently display their photo ID and access cards throughout the day. The zipper ensures the card is not accidentally dropped or misplaced when moving between secure zones, such as server rooms or executive floors. The clear design allows security personnel to verify identity quickly without requiring the employee to remove the card.

Healthcare and Laboratories: In hospitals and clinical labs, hygiene and safety are paramount. Healthcare professionals use plastic badge holders with zippers to keep their IDs clean and free from exposure to pathogens, spills, or chemicals. The ability to wipe down the plastic surface with disinfectant solutions is a critical feature. The breakaway lanyard prevents accidents by detaching if caught on equipment, protecting the staff from injury.

Manufacturing and Industrial Sites: On factory floors and construction sites, dust, moisture, and physical impact are constant threats to paper or unprotected plastic cards. The sealed plastic holder protects the essential safety training certifications or access credentials from damage. The robust clip allows it to be securely fastened to a hard hat or tool belt, keeping hands free while maintaining immediate access to required identification.

Events and Conferences: Event organizers issue temporary badges to attendees, speakers, and VIPs. A zippered holder protects this often single-use credential for the duration of the event, preventing loss and ensuring smooth access to different venues. The holder itself can be branded with logos, serving as an additional marketing tool for the organizers.

Education Institutions: In schools and universities, students and faculty use these holders to carry student IDs, library cards, and meal plan cards. The durability of the holder protects the cards from daily wear and tear in backpacks and pockets, and the zipper prevents them from falling out.

Maintenance and Care

Proper maintenance extends the functional lifespan of a plastic badge holder significantly. For routine cleaning, use a soft, lint-free cloth slightly dampened with a mild soap solution or isopropyl alcohol (with a concentration no higher than 70%) to wipe the exterior and the clear plastic window. Avoid using abrasive cleaners, solvents like acetone or bleach, or rough paper towels, as these can create micro-scratches on the surface, reducing clarity and promoting cloudiness over time.

To clean the zipper mechanism, a small, soft-bristled brush (e.g., a clean, dry toothbrush) can be used to gently dislodge any accumulated dust or debris from the teeth. If the zipper becomes stiff, a minimal application of a silicone-based lubricant (not oil-based, as it can attract dirt and degrade the plastic) is recommended. Apply a tiny drop to a cotton swab and run it along the zipper teeth, then work the zipper back and forth to distribute the lubricant evenly before wiping away any excess.

When not in use, store the holder in a cool, dry place away from direct sunlight. Prolonged exposure to UV radiation and extreme temperatures (above 60°C or 140°F) can cause the plastic to become brittle, yellow, and crack. Similarly, avoid storing the holder under heavy objects that could deform its shape or crush the clip mechanism. If the holder incorporates an RFID-shielding layer, take care not to puncture this inner lining, as a compromise to its integrity will reduce its effectiveness against electronic theft.

Regularly inspect the holder for signs of wear, such as cracks along the seams, a fraying lanyard, or a weakening zipper. The attachment clip should be checked to ensure the spring mechanism remains tight and functional. For holders with a breakaway lanyard, test the release mechanism periodically to confirm it functions correctly under the designed pressure, ensuring user safety is not compromised.

English

English